shirt measurements guide for vinyl

Accurate shirt measurements are crucial for perfect vinyl placement․ Whether crafting DIY designs or running a small business, understanding sizing ensures professional results․ This guide provides a comprehensive overview of shirt measurements, addressing common challenges like varying fabric types and fits․ Learn how to measure shirts effectively, choose the right vinyl size, and align designs properly for a polished finish․ Master the fundamentals to achieve flawless vinyl applications every time․

Types of Shirts and Their Sizing Standards

Understanding the different types of shirts and their sizing standards is essential for proper vinyl placement․ Shirt styles vary significantly, from adult T-shirts to youth, toddler, and baby onesies, each with unique measurements․ Adult shirts typically range from Small to 3XL, with chest measurements increasing by approximately 2-3 inches per size․ Youth shirts are smaller, with sizes like Youth Small, Medium, and Large, corresponding to chest widths of 12-16 inches․ Toddler and baby onesies are designed for infants, with sizes based on age and weight, such as 0-6 months or 9-18 months․

The sizing standards for shirts are not universal, as different brands may have slightly varying measurements․ For example, a Youth Large from one brand might be similar to an Adult Small from another․ However, general guidelines provide a reliable starting point for vinyl sizing․ Baby onesies, for instance, often have smaller dimensions, requiring vinyl designs of 3×3 inches for 0-6 months and 5×5 inches for 6-9 months․

When working with shirts, it’s important to consider the intended use and fit; Crew neck shirts and V-neck shirts have different neckline depths, which affect vinyl placement․ Crew necks typically require designs placed 2․5-3․5 inches below the neckline, while V-necks may need adjustments to avoid distortion․ Fabric type also plays a role, as stretchy materials like polyester blends may require slightly smaller designs to maintain proportions․

A printable size chart can serve as a quick reference for shirt measurements and corresponding vinyl sizes․ For adult shirts, designs are often between 9-13 inches wide, while youth shirts range from 6-9 inches․ Toddler shirts and onesies require smaller designs, typically 6×6 inches or less․ Understanding these sizing standards ensures that vinyl designs are proportional and visually appealing on any shirt type․

By familiarizing yourself with the unique measurements of each shirt category, you can create custom vinyl designs that fit seamlessly, regardless of the recipient’s age or shirt style․ This foundational knowledge is key to achieving professional-looking results in vinyl crafting․

Methods of Measuring Shirts

Measuring shirts accurately is a critical step in ensuring proper vinyl placement․ Whether you’re working with adult, youth, or toddler shirts, precise measurements guarantee that your design fits perfectly․ The most common method involves using a measuring tape to determine the width and height of the design area․ For example, the chest area of an adult T-shirt is typically measured across the widest part, just below the armpits, to ensure the vinyl design is centered and proportional․

Another effective method is to use a T-shirt ruler guide, specifically designed for vinyl alignment․ These tools provide marked measurements for different shirt sizes, making it easy to position designs correctly․ For instance, a standard adult T-shirt might have a design area of 11×11 inches, while a youth shirt could be 10․5×10․5 inches․ Toddler shirts and onesies require smaller measurements, such as 6×6 inches for designs․

In addition to measuring tapes and rulers, some crafters use symmetrical folds to ensure alignment․ By folding the shirt in half vertically or horizontally, you can pinpoint the center point for vinyl placement․ This method is particularly useful for ensuring designs are evenly spaced and symmetrical․ For V-neck shirts, measure from the deepest part of the neckline to avoid distortion․

For custom orders, graduated sizing is a valuable technique․ This involves measuring each shirt individually and adjusting the vinyl design to fit perfectly, ensuring consistency across different sizes․ Whether you’re using a DIY setup or professional tools, accurate measurements are the foundation of successful vinyl applications․

By mastering these measurement methods, you can achieve professional-looking results and ensure your vinyl designs are flawlessly aligned on any shirt type․

Standard Vinyl Sizes for Different Shirt Categories

Choosing the right vinyl size for your shirt design depends on the shirt category and intended use․ Adult T-shirts typically accommodate designs ranging from 9 to 13 inches wide, making them ideal for bold logos or graphics․ Youth shirts, designed for teenagers, usually require slightly smaller designs, between 6 to 9 inches wide․ This ensures the design is proportional to the smaller chest area․

Toddler and infant shirts need much smaller vinyl sizes due to their limited space․ For example, baby onesies for 0-6 months typically use 3×3 inch designs, while those for 6-9 months might use 5×5 inches․ Older toddlers (18 months and above) can accommodate slightly larger designs, around 6×6 inches․ These sizes ensure the design is visible without overwhelming the small shirt size․

V-neck shirts require special consideration․ The deeper neckline means designs should be placed lower, typically 1․5 to 2․5 inches below the neckline, to avoid distortion․ Crew neck shirts, with their rounder necklines, allow designs to be placed 2․5 to 3․5 inches below the neckline for optimal visibility․

For center chest designs, adult shirts can handle widths of 6 to 10 inches, while children’s shirts should be around 6 inches wide․ These measurements ensure the design is balanced and visually appealing․ By adhering to these standard vinyl sizes, you can create designs that look great on any shirt category, whether for personal projects or professional orders․

Remember, accurate sizing is key to achieving professional-looking results․ Use these guidelines as a starting point and adjust based on specific design needs and shirt types․ Proper sizing ensures your vinyl designs are both functional and visually appealing․

Placement Guidelines for Vinyl Designs

Proper placement of vinyl designs on shirts is essential for a professional and visually appealing result․ The placement depends on the type of shirt, the design, and the intended look․ Here are some key guidelines to follow:

Center Chest Placement: For adult shirts, center chest designs typically range from 6 to 10 inches in width․ This size ensures the design is prominent without overwhelming the shirt․ For children’s shirts, the design should be smaller, around 6 inches wide, to maintain proportion․ The design should be centered and placed 3 to 3․5 inches below the neckline for crew neck shirts; For V-neck shirts, place the design 1․5 to 2․5 inches below the deepest part of the V to avoid distortion․

Upper Back Placement: Designs on the upper back are usually larger than chest designs․ For adult shirts, they can range from 9 to 11 inches wide, depending on the design․ Align the top of the design with the center of the shoulders for a balanced look․ This placement works well for logos, slogans, or intricate graphics․

Sleeve Placement: Vinyl designs on sleeves are smaller and more subtle․ They typically range from 4 to 5 inches in width․ Place the design midway between the shoulder and the cuff for a balanced appearance․ This is ideal for smaller logos or text․

Hem Placement: Designs on the hem are usually wider and can range from 8 to 10 inches in width․ Center the design at the bottom of the shirt, ensuring it aligns with the center of the shirt․ This placement is great for decorative elements or additional text․

General Tips: Always use a ruler or alignment tool to ensure the design is centered and symmetrical․ Measure the width of the shirt to ensure the vinyl fits comfortably․ For V-neck shirts, adjust the placement to avoid the neckline overlapping the design․ By following these guidelines, you can achieve professional-looking vinyl placements that enhance the overall appearance of the shirt․

Tools and Guides for Vinyl Alignment

Aligning vinyl designs on shirts can be tricky, but with the right tools and guides, achieving professional results becomes much easier․ Proper alignment ensures that designs are centered, symmetrical, and visually appealing․ Below are some essential tools and guides to help you master vinyl alignment:

Measuring Tape: A measuring tape is a fundamental tool for determining the width of the shirt and ensuring the vinyl design fits perfectly․ Measure the chest, sleeves, and hem to understand the available space for your design․

Alignment Ruler: An alignment ruler is specifically designed for vinyl placement․ It provides clear measurements and guidelines to center designs accurately․ Look for rulers with markings for different shirt sizes and design types․

Heat Transfer Alignment Guides: These guides are placed on the shirt to help position the vinyl design correctly․ They often feature centering lines and measurements for chest, sleeve, and hem placements․ Some guides are reusable and can be adjusted for different shirt sizes․

Acrylic T-Shirt Ruler: This tool is popular among crafters and small businesses․ It provides a sturdy surface to measure and align vinyl designs․ The ruler often includes markings for standard shirt sizes and design placements, making it versatile for various projects․

Printable Alignment Templates: Printable templates are a cost-effective solution for DIY crafters․ They can be downloaded online and printed at home․ Place the template on the shirt, align the vinyl design with the markings, and iron it on․ Templates are available for different shirt types and design sizes․

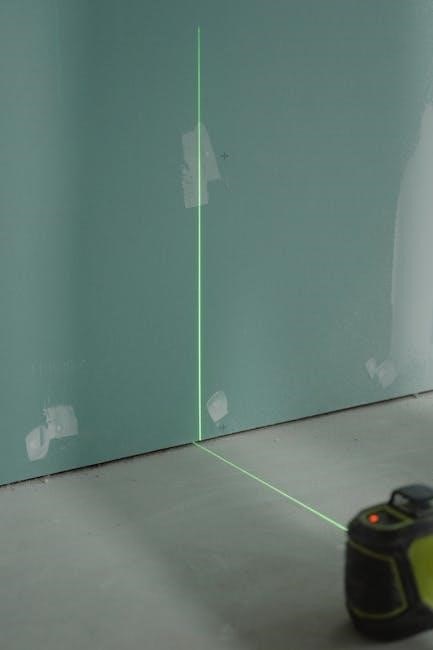

Laser Alignment Tools: For professional setups, laser alignment tools provide precise guidance․ These tools project a laser line onto the shirt, helping to center the design perfectly․ They are especially useful for large-scale productions or intricate designs․

Using these tools and guides ensures that your vinyl designs are properly aligned, enhancing the overall appearance of the shirt․ Whether you’re a DIY crafter or a professional, investing in the right tools will save time and improve the quality of your work․

Graduated Sizing for Custom Orders

Graduated sizing is a technique used to ensure that vinyl designs are proportionally scaled to fit different shirt sizes․ This method is particularly useful for custom orders, where consistency across various shirt sizes is essential․ By adjusting the size of the design relative to the shirt size, you can maintain a professional and visually appealing appearance․

For example, a design that measures 10 inches wide for an adult large shirt might be scaled down to 9 inches for a medium and 8 inches for a small․ This gradual reduction ensures that the design remains balanced and does not appear oversized or undersized on smaller shirts․ Similarly, youth and toddler shirts require even smaller designs, typically ranging from 6 to 8 inches in width․

Graduated sizing also applies to the height of the design․ While the width is often the primary focus, the height should be adjusted proportionally to maintain the design’s integrity․ For instance, a design that is 12 inches wide and 6 inches tall on an adult shirt might be reduced to 9 inches wide and 4․5 inches tall on a youth shirt․

When implementing graduated sizing, it’s important to consider the shirt’s intended use and the design’s complexity․ Simple designs, such as text or logos, can be scaled more aggressively, while intricate designs may require more careful adjustment to ensure clarity and legibility․ Additionally, the placement of the design should be consistent across all shirt sizes, with adjustments made to accommodate different neckline styles and sleeve lengths․

Graduated sizing is a valuable practice for both DIY crafters and professional vinyl applicators․ It enhances the overall quality of custom orders and ensures that each shirt, regardless of size, looks polished and well-designed․ By following graduated sizing guidelines, you can deliver consistent results that meet your customers’ expectations․

Troubleshooting Common Issues

When working with vinyl on shirts, several common issues can arise, ranging from sizing discrepancies to alignment problems․ Addressing these challenges effectively ensures professional-looking results․ Below are some of the most frequent issues and practical solutions to resolve them․

Issue: Vinyl Design Too Large or Too Small

One of the most common problems is a vinyl design that doesn’t proportionally fit the shirt․ To avoid this, always measure the shirt’s chest width and compare it to the design size․ For example, adult shirts typically accommodate designs between 9 to 13 inches wide, while youth shirts require smaller sizes (6 to 9 inches)․ Using a sizing chart or ruler can help ensure accuracy․

Issue: Misaligned Designs

Misalignment is another frequent issue, especially on V-neck shirts or irregularly shaped garments․ To fix this, measure the distance from the neckline to the design placement․ For crew necks, place the design 2․5 to 3․5 inches below the neckline, while V-necks require placement 1․5 to 2․5 inches below the deepest part of the V․ Using alignment tools or guides can also help achieve symmetry․

Issue: Distorted Designs

Distortion can occur when the vinyl is stretched or applied unevenly․ To prevent this, ensure the shirt is laid flat and smooth before applying the vinyl․ For sleeve or pocket designs, measure the available space carefully and avoid stretching the fabric during the application process․

Issue: Inconsistent Placement Across Sizes

When creating custom orders for multiple shirt sizes, designs may appear inconsistent if not scaled properly․ Graduated sizing is key—reduce the design size proportionally for smaller shirts․ For instance, a 10-inch design for an adult large might be scaled to 8 inches for a small․ This ensures a balanced look across all sizes․

By addressing these common issues with careful measurement, proper alignment, and proportional scaling, you can achieve flawless vinyl applications and deliver high-quality results every time․

Printable Size Chart for Quick Reference

Having a printable size chart is essential for quick and accurate vinyl placement on shirts․ Below is a concise reference guide that outlines standard measurements for various shirt sizes and corresponding vinyl design dimensions․ Print this chart and keep it handy for easy access during your vinyl application projects․

Adult T-Shirt Measurements and Vinyl Size Guide

| Shirt Size | Chest Measurement (inches/cm) | Recommended Vinyl Size (width x height) |

|---|---|---|

| Small | 18-20 inches / 45․7-50․8 cm | 9×9 inches / 22․9×22․9 cm |

| Medium | 20-22 inches / 50․8-55․9 cm | 10×10 inches / 25․4×25․4 cm |

| Large | 22-24 inches / 55․9-61 cm | 11×11 inches / 27․9×27․9 cm |

| X-Large | 24-26 inches / 61-66 cm | 11×11 inches / 27․9×27․9 cm |

Youth and Toddler Shirt Measurements

| Shirt Type | Size/Age Range | Recommended Vinyl Size (width x height) |

|---|---|---|

| Youth T-Shirt | Medium/Large | 10․5×10․5 inches / 26․7×26․7 cm |

| Toddler T-Shirt | 2-3 years | 6×6 inches / 15․2×15․2 cm |

| Baby Onesie | 0-6 months | 3×3 inches / 7․6×7․6 cm |

General Placement Guidelines

- Crew Neck Shirts: Place design 2․5-3․5 inches below the neckline․

- V-Neck Shirts: Place design 1․5-2․5 inches below the deepest part of the V․

- Center Chest Designs: Ensure the design is centered and aligned with the shirt’s midpoint․

Print this chart on sturdy paper or cardstock for a durable reference tool․ Use it alongside a measuring tape or alignment guide to ensure precise vinyl placement and professional results․

Tips for Aligning Text and Images

Aligning text and images correctly on shirts is vital for a professional and visually appealing result․ Proper alignment ensures that your vinyl designs look balanced and centered, enhancing the overall appearance of the finished product․ Here are some practical tips to help you master the alignment process:

Centered Designs

For centered designs, measure the width of the shirt’s chest area to determine the midpoint․ Use a ruler or measuring tape to find the center point, and align the center of your vinyl design with this mark․ Fold the shirt in half horizontally to create a symmetrical guide for precise placement․

Symmetrical Text

When working with text, ensure the letters are evenly spaced and symmetrical․ Measure the width of the text design and compare it to the shirt’s chest width to avoid overcrowding․ Use a laser guide or grid alignment tool to achieve perfect symmetry, especially for names, logos, or phrases․

Multi-Line Text Alignment

For multi-line text, align each line individually to maintain balance․ Start by centering the top line, then measure the spacing between each subsequent line to ensure uniformity․ Use a small ruler or alignment tool to adjust the placement of each line for a polished look․

Image Alignment

For image-based designs, focus on the shirt’s natural symmetry points, such as the center of the chest or the midpoint of the back․ Use a measuring tape to mark the center point, then align the image’s center with this mark․ For larger images, ensure the design fits within the shirt’s printable area without stretching or distortion․

V-Neck and Crew Neck Adjustments

Adjust your alignment based on the shirt style․ For V-neck shirts, place designs slightly lower than the deepest part of the V․ For crew necks, align the design 2․5-3․5 inches below the neckline․ This ensures the design looks proportional and well-positioned․

General Tips

- Use a shirt alignment tool or ruler for precise measurements․

- Preview your design on a digital mockup before cutting vinyl․

- Double-check the shirt’s measurements to ensure the design fits comfortably within the intended area․

By following these alignment tips, you can achieve professional-looking results for your vinyl projects․ Whether you’re working on a single custom order or producing bulk designs, proper alignment is key to delivering high-quality, visually appealing shirts․

Best Practices for Specific Shirt Styles

Different shirt styles require tailored approaches when applying vinyl designs․ Understanding the unique characteristics of each style ensures optimal placement and a professional finish․ Below are best practices for popular shirt styles:

Crew Neck Shirts

Crew neck shirts are the most common and versatile․ For adult sizes, center designs between 8-12 inches wide on the chest, placing them 2․5-3․5 inches below the neckline․ This ensures visibility without overwhelming the design area․ For youth sizes, reduce the width to 7-10 inches and adjust placement proportionally․

V-Neck Shirts

V-neck shirts require careful alignment due to their deeper neckline․ Place designs 1․5-2․5 inches below the lowest point of the V to maintain balance․ This adjustment prevents the design from appearing too high or asymmetrical․ Use a measuring tape to mark the midpoint of the V for precise centering․

Hoodies and Sweatshirts

Hoodies offer a larger canvas, but placement is critical․ Center designs on the chest, 4-6 inches below the neckline, or opt for a larger design spanning 10-12 inches wide across the back․ Ensure the vinyl aligns with the hoodie’s seams for a seamless look․ Avoid placing designs too close to the pocket or hood for a cleaner aesthetic․

Baby Onesies

For baby onesies, smaller designs work best․ Use a 3×3 inch size for infants (0-6 months) and 5×5 inches for toddlers (6-18 months)․ Place designs 2-3 inches below the neckline, centered on the chest․ Keep text simple and images cute to suit the target audience․

Scoop Neck and Deep V-Neck Shirts

Scoop necks and deep V-necks are stylish but challenging․ Position designs 1․5-2 inches below the neckline’s lowest point, ensuring the vinyl aligns with the shirt’s natural curves․ Use a ruler or alignment tool to maintain symmetry and avoid distortion․

Sleeveless Shirts

Sleeveless shirts require a different approach․ Place smaller designs (6-8 inches wide) on the chest, 2-3 inches below the armhole․ For larger designs, center them on the back, ensuring they fit within the shirt’s width and avoid the armholes․

By following these best practices for specific shirt styles, you can achieve professional-looking vinyl applications tailored to each garment’s unique features․ Remember to measure carefully and adjust designs based on the shirt’s fit and style for optimal results․

Considerations for DIY vs․ Professional Setups

When working with shirt measurements for vinyl, the approach differs significantly between DIY projects and professional setups․ Understanding these differences is key to achieving the best results in either context․

DIY Setups

For DIY enthusiasts, simplicity and accessibility are prioritized․ Basic tools like a measuring tape, iron, and cutting mat are often sufficient․ DIY projects typically involve smaller quantities, allowing for more flexibility in design and placement․ However, precision can be challenging without specialized equipment․ To overcome this, DIYers often rely on printable guides and online templates to ensure accurate measurements and alignment․

Professional Setups

Professional setups require precision, consistency, and efficiency․ Heat presses, laser cutters, and advanced software are essential for high-volume production․ Professionals must adhere to strict sizing standards to meet customer expectations․ Tools like alignment rulers and graduated sizing charts are indispensable for maintaining uniformity across orders․ Additionally, professionals often invest in durable, high-quality vinyl to ensure long-lasting results․

Key Differences

The primary difference lies in scalability and precision․ DIY projects focus on creativity and personalization, while professional setups emphasize consistency and reliability․ Professionals must also consider factors like material durability, production time, and cost efficiency, which are less critical in DIY contexts․

Mastering shirt measurements for vinyl is essential for achieving professional and visually appealing results, whether for DIY projects or commercial production․ Throughout this guide, we’ve explored the fundamentals of shirt sizing, measurement techniques, and best practices for vinyl placement․ Understanding these principles ensures that your designs are proportionate, well-aligned, and visually striking․

A key takeaway is the importance of using standardized sizing charts and measurement tools․ These resources help eliminate guesswork and ensure consistency across different shirt types and sizes․ Additionally, considering the specific fabric, neckline, and intended design use case is crucial for optimal placement and durability․

For DIY crafters, simplicity and accessibility are vital․ Investing in basic tools like a measuring tape and alignment guides can significantly improve results; Professionals, on the other hand, must prioritize precision and scalability, often requiring advanced equipment and software to meet high-volume demands․

Regardless of the setup, the core principles remain the same: accurate measurements, proper alignment, and attention to detail; By following the guidelines outlined in this guide, you can create stunning, long-lasting vinyl designs that satisfy both personal creativity and customer expectations․